Silicone rubber is an indispensable material for the manufacturers of automotive and transportation vehicles. The automotive silicone market grows annually due to silicone’s stability and other advantages, including weather resistance, high temperature resistance and moisture resistance. As a sustainable material to replace plastic, silicone is widely applied to different types of automotive parts.

Silicone Properties in Automotive Industry

As the sustainable movement rises up, the eco-friendly feature of silicone makes it a main choice for electronic vehicles (EVs) manufactures. The use of silicone also improves product performance and safety.

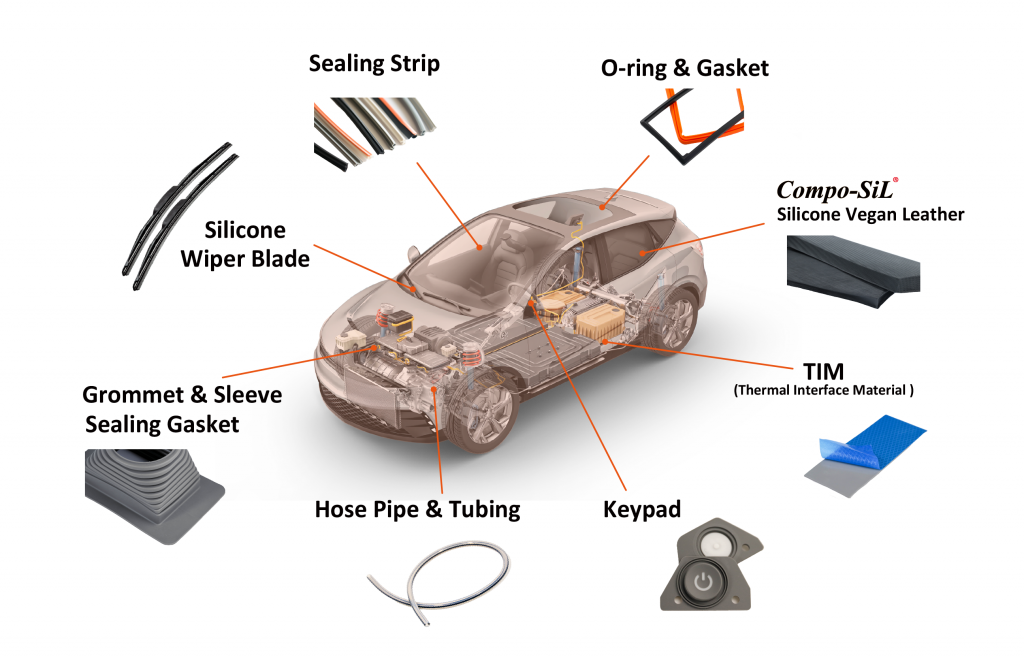

Field of Application

1. Silicone keypad and button (all kinds of keypad, car dashboard, central control panel, etc.)

2. Silicone parts (o-ring, sealing gasket, sealing strip, silicone wiper blade, hope pipe, tubing, etc.)

3. High-performance thermal conductive silicone sheet (xenon lamp ballast, car stereo system and telematics device, etc.)

4. Silicone foam cushion (shock absorber, heat preservation, high and low temperature soundproofing, EV battery protection, etc.)

5. Others (grommet, sleeve, coil sheaths, automotive turbocharger cooling pipes)

6. Compo-SiL® (automotive interior, automotive door trim, in-mold decoration & out-mold decoration process material, human machine interface (HMI))