General Silicones (GS) not only masters the supplying sources of silicone raw materials from many world-renowned brands, but also has more than 50 years of technical expertise in silicone material processing. Therefore, GS is able to customize the hardness, color, tear strength, resilience, and other special properties or functions of silicone materials according to customer’s actual requirements.

Material Formula Design and Compound Capability

Mold/Tooling Design and Developing Capability

GS has the capability of design mold/tooling and making it by using CNC machines. In the product developing stage, sample mold/tooling can be quickly developed in order to provide valued clients with actual prototypes so that to test its dimensions, appearance, and operability at the earliest time; and hence shorten the development timeliness and increase success rate of product developing.

GS has made long-term investment in R&D of advanced technology specializing in mold/tooling design, silicone molding processes, and surface treatment for inner mechanism parts and exposed parts not covered by housing. As the quality of the mold/tooling will directly affect the quality of product and its production yield. By utilizing decades of accumulated experience in mold/tooling making, GS can efficiently satisfy the quality requirements of mold/tooling and provide customers with the best solutions.

Professional Multi-process Capability

Compression molding:Suitable for making a variety of special-shaped silicone parts, electronic parts like keypad, button, waterproof rings, gasket, and consumer products such as silicone pacifier and silicone bracelet, etc.

Injection molding: Products undergoing injection molding process are quite similar to that of compression molding. The major difference is liquid silicone materials are used for injection molding, whereas solid silicone rubber is used for compression molding.

Extrusion molding::Suitable for making diverse kinds of silicone strips and tubing. It moreover can be extruded in three colors simultaneously, such as sealing edge strips, silicone tubes for connecting drinking liquids, etc.

Sheet calendering:Suitable for making all kinds of silicone sheet, pad and film, especially for electronics application like shielding sheet, hot press cushion sheet, thermal interface materials (TIM), and applications in various industrial products or daily supplies

Customized Surface Treatment Capability

Back-end technical processing includes silk screen printing, laser etching, spray coating, hard coating (epoxy coating), grinding, bonding, and die-cutting.

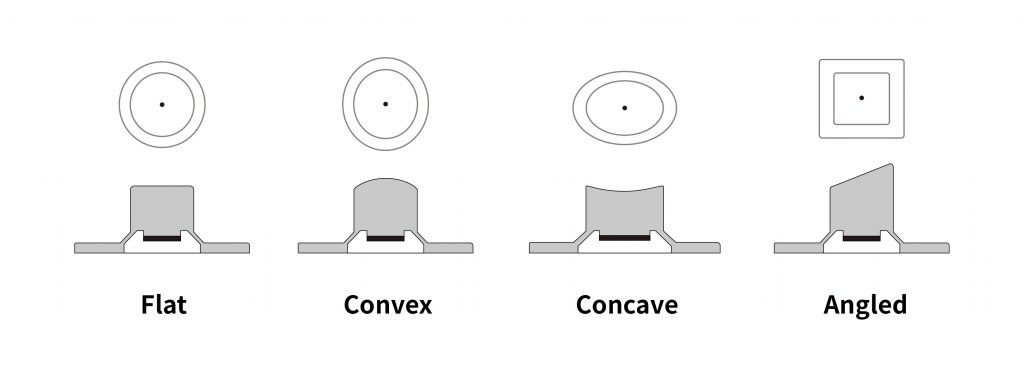

- Key Appearance Designs:

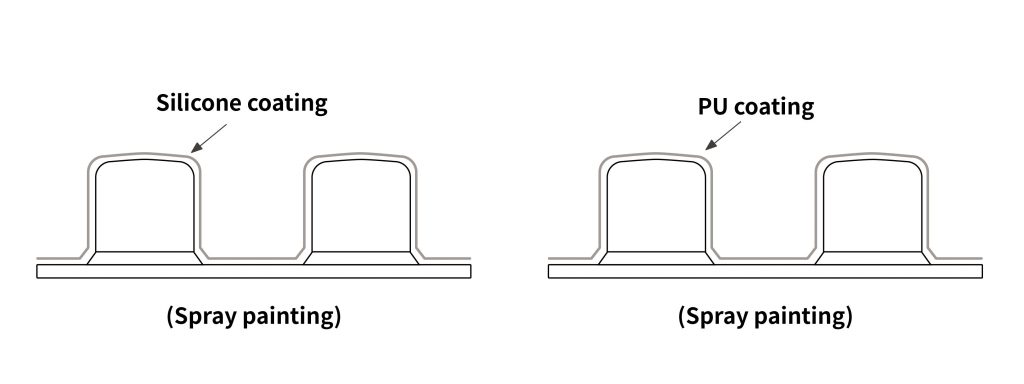

- Surface Coating:

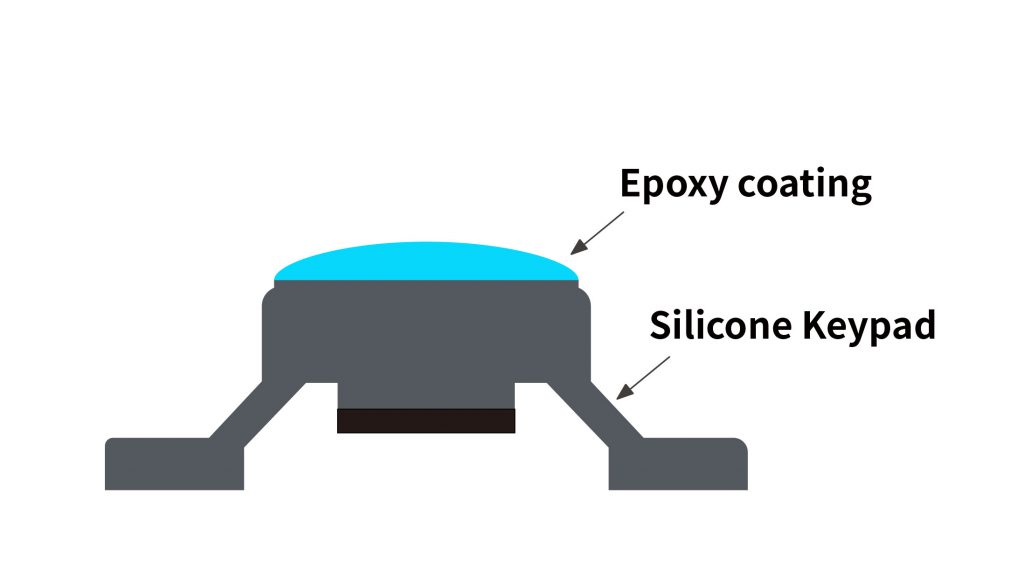

- Hard Coating (Epoxy coating):

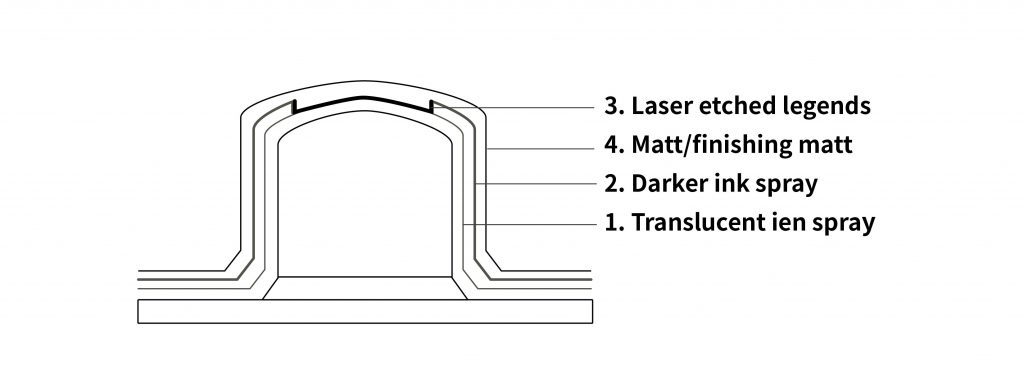

- Laser Etching

Strict and Complete Quality Management System

GS has accumulated more than 50 years of experience in silicone products manufacturing, and upholds a high quality requirement to its products. Silicone rubber products made by GS are compliant to ISO 9001 and IATF 16949 standard certifications. GS is also ISO 14001 certified, and has established a rigorous strict complete quality control system.